A case study about how a light-curable adhesive replaced a two-part epoxy for faster sensor assembly and improved the application process. ...

Aerospace Improving PCB Conformal Coating Process

A case study on improving the PCB conformal coating process by increasing production output.

Challenge

Find a coating with no solvents added and with a high dry thickness that will protect against corrosion caused by gas and salt.

The customer was developing a new industrial inverter model that required a high dry thickness of conformal coating to meet electrical performance. The product they were using at the time was a solvent-based coating with a low dry (25um/0.001 in) thickness. Air pollution and odor from solvent-based coatings were also a huge concern as the employees’ health was at risk.

Solution

Dymax 9482 conformal coating is engineered for coating thicknesses up to 25 um (0.010 in) and offers superior protection to alternative products. The Dymax Edge Carry Conveyor was customized to boost productivity.

Committed to nurturing collaborative partnerships with customers, the Dymax Application Engineering team worked closely with the company to come up with an innovative solution to protect the PCBs from harsh environments. The manufacturer needed an environment-friendly conformal coating that did not crack, delaminate, or show signs of corrosion while maintaining mechanical and electrical properties after testing. Once the reasearch and testing on the customer’s parts was completed dual-cure 9482, a light-curable secondary moisture-cure coating, was recommended to ensure complete cure of coating that flowed underneath components on printed circuit boards.

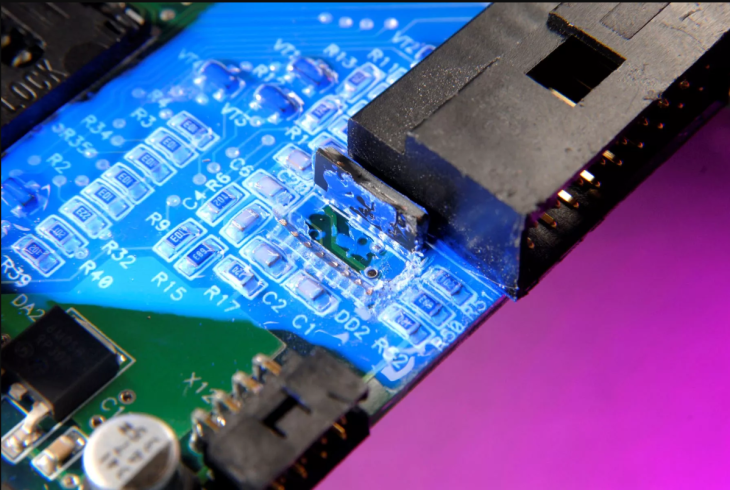

This material achieved a UL 94-V0 flammability rating up to 10 mils thick which made it ideal for environmental protection of PWBs, wire harnesses, electronic components, and other surfaces needing a protective coating. It passed thermal shock requirements from -55°C and up to 135°C at 10 mils, and protected against moisture, condensation, dust, dirt, salts, chemicals, abrasion, thermal shock, mechanical shock, and other factors that can all affect circuit performance. Dymax 9482 was ideal for the customer’s application since it is engineered for coating thicknesses up to 25 um (0.001 in) and becomes tack free immediately after light curing, helping to avoid handling defects and reduce processing time and costs. In addition, it has no solvents added and fluoresces vivid blue when exposed to UV light (365 nm) for easy post-cure inspection.

To speed curing time our application engineers suggested using a Dymax Edge Carry Conveyor system. The conveyor was customized to a six-lamp system to optimize their production process. Rapid curing allowed the coated boards to swiftly move onto the next step in the manufacturing process with virtually no down/wait time.

Results

Dymax solutions system helped the customer increase output by 30%.

The customer was very satisfied with how our total Dymax system solution improved their process. 9482 provided the ideal coating with no cracking or delamination, while the customized conveyor cured the boards in seconds, allowing the customer to increase output by 30%.

Related Products

Check out the other Dymax products that work in conjunction with this one to create a complete solution

Product Number

Product Description

Regional Availability

Check out the other Dymax products that work in conjunction with this one to create a complete solution

More Case Studies

We offer more than products, we offer solutions. See how Dymax is helping customers solve their most challenging applications in various markets.

View allAdhesive Replaces 2-Part Epoxy for Faster Optical Sensor Assembly

Aerospace Improving PCB Masking Process

A case study on improving the PCB masking process for an aerospace and defense manufacturer. ...

Aerospace Masking Process for Electroless Nickel Plating

A case study on the masking process for electroless nickel plating ...

Aerospace Printed Circuit Board Assembly

Increasing Production and Reducing Processing Time in PCB Assembly ...

Automated Masking System Revolutionizes Surface Treatment Processing

A case study about how an automated masking line drastically reduced the processing times required for an aero engine component. ...

Bonding MLAs in Automotive Headlights

Adhesive for Bonding MLAs in Automotive Headlights Exhibits Low Discoloration Under High Temperatures ...

Cinch Gaming Controllers Get Enhanced Grip

Cinch Gaming, a national leader in custom professional video game controllers, was looking for a durable solution to provide a rubber grip coating to their ABS plastic controller shells. ...

Electrical Explosion Protection & Sensor Technology

A world leader in electrical explosion protection and sensor technology was looking to turn away from laser welding for an application that requires sealing two polycarbonates of their photoelectric ...

GenZe Electric Transportation Battery Pack Gasket

Using a form-in-place gasket to create a reliable battery assembly that meets strict design standards of weight, performance, and safety. ...

High Performance Solutions for EV Charging Stations

A case study on how light-curable conformal coatings and encapsulants helped improve EV smart charging station infrastructure PCB applications. ...

Light-Curing Conveyor Enables 100% Manufacturing Scale Up

A case study on how using Dymax UVCS Light-Curing Conveyor Systems helped to increase the production of nasal swabs.VIDEO: Dymax Partners with 3D Printer Company on COVID-19 Test Swabs #InThisTogeth...

One Part, Optical Epoxy Using UV/Visible Light and Heat Cure

A case study on using ultraviolet and heat cure to secure a camera module holder to a PCB. ...

Ruggedizing Lens and Reflector Housings in Flashlights

A leading manufacturer of premium portable lighting wanted to ruggedize its safety flashlights used in the field by firefighters, police officers, and military troops. In their search for a fast-curi...

Ultra-Red Fluorescing Technology Provides Immediate Quality Check

A case study on how the use of patented Ultra-Red® fluorescing technology can aid in product verification. ...

Get In Touch

Interested in learning more or have questions? We want to hear from you.